From the beginning, that is, since 1998, the company has engaged in high temperature galvanizing (hot-dip coating).

Immersion is a method widely used for protection of steel from corrosion.

This will be galvanized into a liquid about 540°C – 580°C hot molten zinc . It is the possibility to expand to thoroughly cover even with complex shapes.

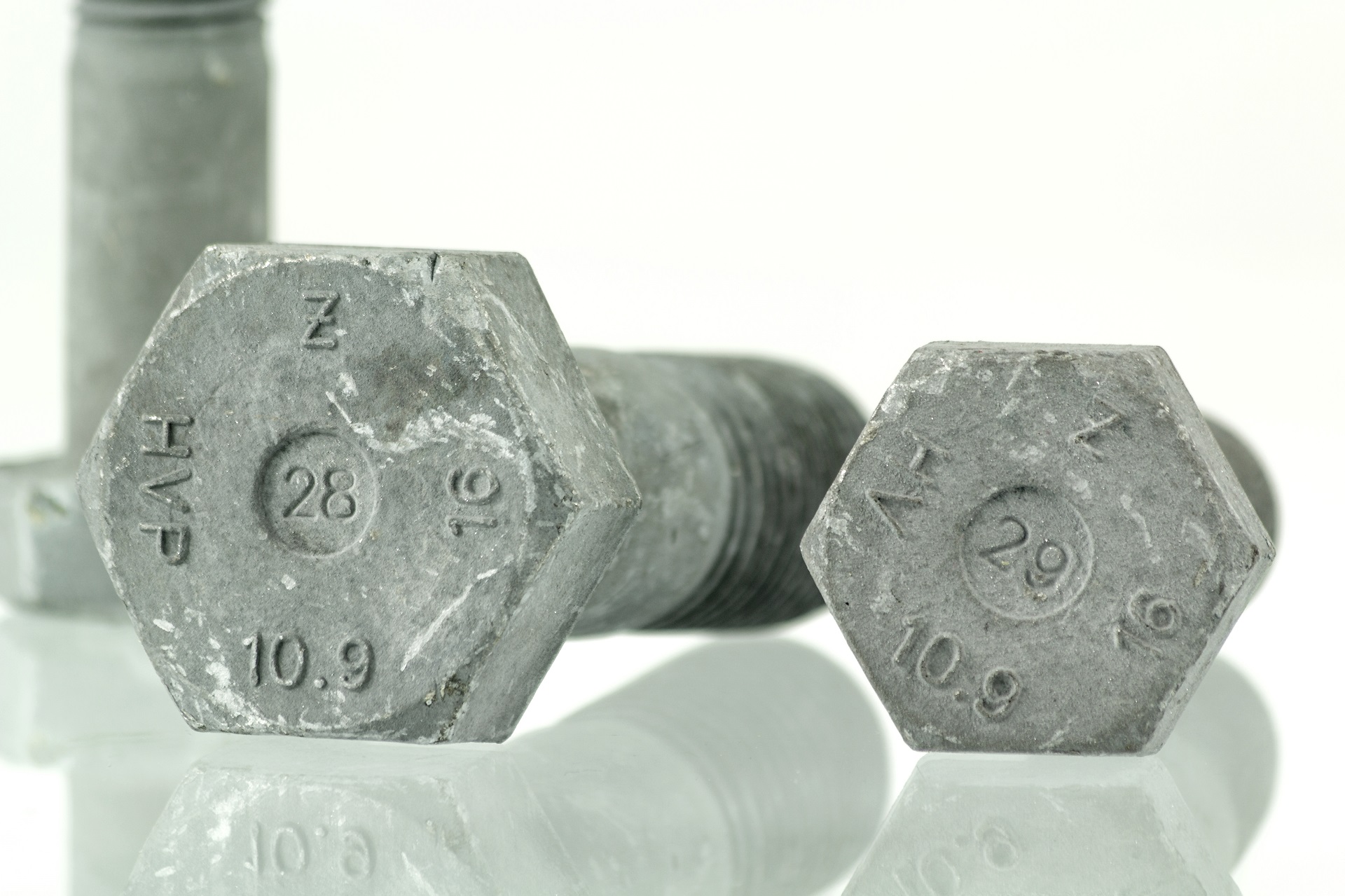

The final product of the hot-dip galvanizing is the coating which resistant to corrosion, abrasion and mechanical damage. Depending on the thickness of the coating, the aggressiveness of the environment and the mechanical erosion, the coating can achieve a protection period between 10 and 100 years. The result of this solution is an aesthetic anticorrosive coating with excellent technical parameters. Basement for galvanizing are the PN EN ISO 10684 and PN EN ISO 1461.